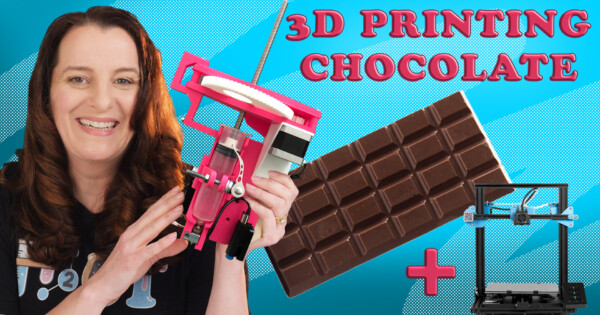

This mission has concerned an enormous studying curve. Optimistically I hoped that I might merely obtain an current paste extruder 3d mannequin, print it after which make some small tweaks. As a substitute I found that the prevailing extruders didn’t work for tremendous extrusion by means of a nozzle. That meant that I wanted to study gear ratios and make a brand new 3d mannequin in blender. When you’ve ever used blender you’ll know that it’s not a straightforward program for freshmen. Weeks later and I lastly created a mannequin that works.

Sooner or later I’d like to tinker with the design and add a heating pad and thermistor to the syringe to permit for chocolate printing, this might be wired in the place the printer at present controls the mattress temperature. Presently solely the nozzle is heated utilizing the heater block.

To make this mission you’ll need:

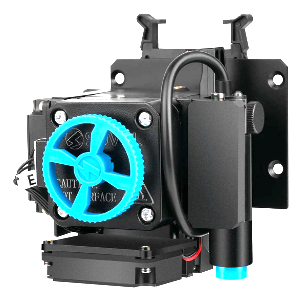

* Sovol svo6 3d printer

* PLA filament in no matter color you need to print your extruder.

* An additional sovol sv06 printer head. ($49) I purchased mine instantly from sovol3d.com. Look below spare elements, this provides you the motor, warmth block with thermistor and nozzle, inductive proximity sensor change for Z probe auto mattress leveling, the mount for that sensor, adapter board PCB breakout module and all of the little cables that join these elements collectively. You don’t want the followers so you may unplug these from the PCB.

* Digital cable and a soldering iron – to elongate the motor cable.

* A 60mL (2.03 fluid ounces) luer lock syringe

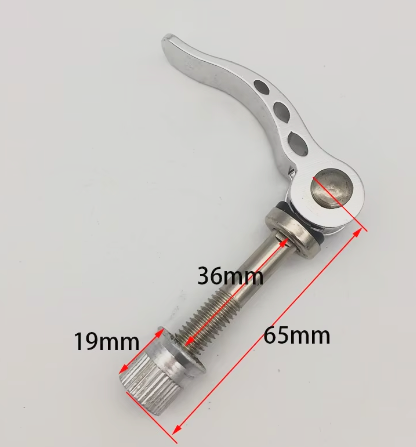

* 1 Bicycle Fast Launch Seat Submit Clamp ($2.50 on aliexpress)

* T8 Lead Screw and Nut Diameter 8mm Pitch 2mm Size 200mm

* A bigger printer nozzle, I used a 1.5mm. In case you are intending on utilizing this within the meals business you’ll need to supply a chrome steel one.

* An adapter to connect the luer lock syringe to the highest of the warmth block (luer to m6 thread adapter). These value about $1 on aliexpress

* A silicone mat to print onto and two sturdy magnets to carry it in place. I did attempt utilizing baking paper however the meals didn’t grip nicely sufficient to print.

* screws and nuts to place it altogether:

3 x Hex Socket Head Cap Bolt diameter M3 length 75 to 80mm

2 x Hex Socket Head Cap Bolt diameter M3 length 50mm

2 x Hex Socket Head Cap Bolt diameter M3 length 10mm

2 x Hex Socket Head Cap Bolt diameter M3 length 35mm

2 x Hex Socket Head Cap Bolt diameter M3 length 8mm these ones need to be low profile for clearance, ie the top head bit can’t be too thick

7 x M3 nuts

Optional if you want to try and make this work for chocolate:

* Heating pad a suitable size to wrap around the syringe (these are available on aliexpress search for electric heating pad 3d printer)

* Flexible aluminium sheet to stick the heating pad on to and wrap around the syringe, this way the syringe can still be washed

* A thermistor

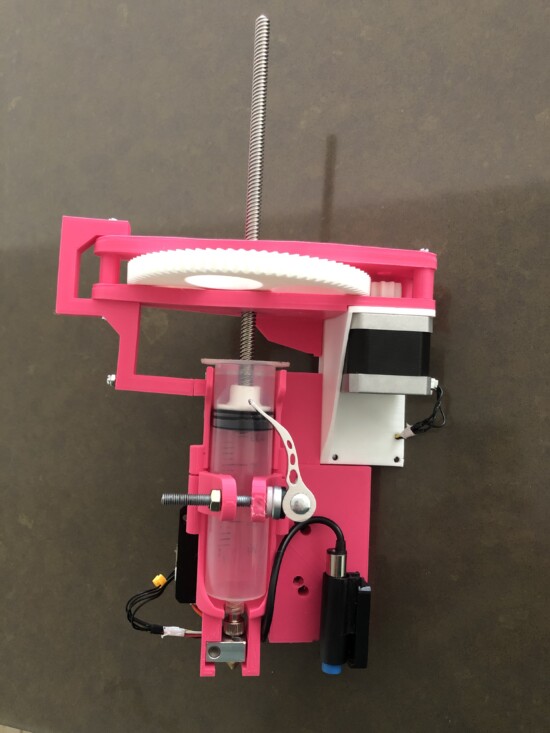

After finishing the video I made some more refinements to the model. Those changes were: lengthen the top and bottom gear holders to accomodate the bigger gear, lengthen the bracket, make the hinges stronger, add a place to attach the sensor, add a holder for the heater block to sit and decrease the depth behind the syringe so that the PCB board sits closer to the heat-block and the cables are not as stretched. There were also other slight changes to screw positions. After making all those changes the model was not manifold and would not slice to 3D print, so I ended up having to pay someone who knew a lot more about blender than me to fix the non-manifold issue. So as much as I intended to make this free – hopefully you now understand why it is not.

* My STL files to download and print on your 3d printer

Above is the, almost, current version printed out and assembled. I have since thickened up the support bracket, because now that it is longer it needs to be stronger.

Or if you want to print the first models shown in the video (note they are not strong enough to extrude through a nozzle but a good starting point if you want to design your own) first one, second one and another one.

To set up the extruder on the printer

Turn off the printer and unplug from the wall.

Unplug the main cable to the printer head pcb.

Undo the 3 screws that hold the printer head in place and carefully store the printer head so that you can print with filament again later.

Add the extruder into place and attach using the same 3 screws.

Plug the cable into the printer head pcb (it won’t work if you forget this step).

Plug the printer in to the wall and turn it on.

Set z offset, to do that select bed leveling / probe z offset and then adjust the height of the nozzle manually (NOTE do not choose auto home as it requires the nozzle to heat up very hot – which will melt the syringe and PLA holder).

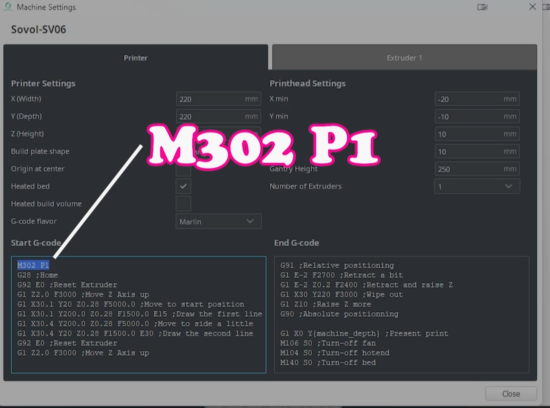

When slicing your model in sovol cura choose SVOL-SVO6 from the top tab then manage printers / machine settings / extruder 1

Take a screenshot of what these settings are normally so that you can change it back later when you swap back to filament.

Change the nozzle size to match the nozzle that you purchased, mine was 1.5mm.

Click on the printer tab and in the start gcode box add:

M302 P1 then close this popup

click on normal on the top tabs and depending on what you are printing make changes here to the nozzle temperature, bed temperature (I set mine to 15C (59 degrees Fahrenheit) so it did not heat, because the room was warmer than that) and also play with layer height and line width. This will vary depending on what food you print.

Once you are printing you can alter the settings on the printer itself, look under tune for speed and flow. Slowing the print speed down to 10-20% significantly improved the output for food printing.

Things to try printing: nutella, whipped butter, cream cheese, chocolate ganache, frosting or basically anything that you would be able to pipe from a normal piping bag through a fine nozzle.

To swap back to filament printing

On the printer itself turn it off and unplug from the wall.

Swap back to the normal print head – remember to plug the cable into the printer head.

Turn it back on then on the printer screen select: configuration / restore defaults

Then calibrate the printer – most importantly set the probe z offset.

In sovol cura delete M302 P1 from the gcode and change the settings in manage printers / machine settings / extruder 1 and printer back to normal then close those tabs

On the main cura screen click on normal to open print settings, next to profile choose a different profile such as fine. Cura will ask you do you want to keep or discard the changes you made to settings. Click ‘discard’ and all the layer height, line width etc will go back to standard. You can now select the ‘normal’ profile and it will be the standard settings.

My Cookbook

Stores that sell my book listed by country:

http://bit.ly/ARcookbook

All recipe quantities in the book are in grams, ounces and cups.